How do cartridge heaters work? Cartridge heaters, commonly used in die casting, moulding, and even in the food and medical industries, contain a ceramic core and resistance coil. When activated, the coil heats up, transferring heat to the surrounding material through an outer metal sheath.

At Cartridge Heaters UK, we supply high quality cartridge heaters in a range of sizes to suit the requirements of any client.

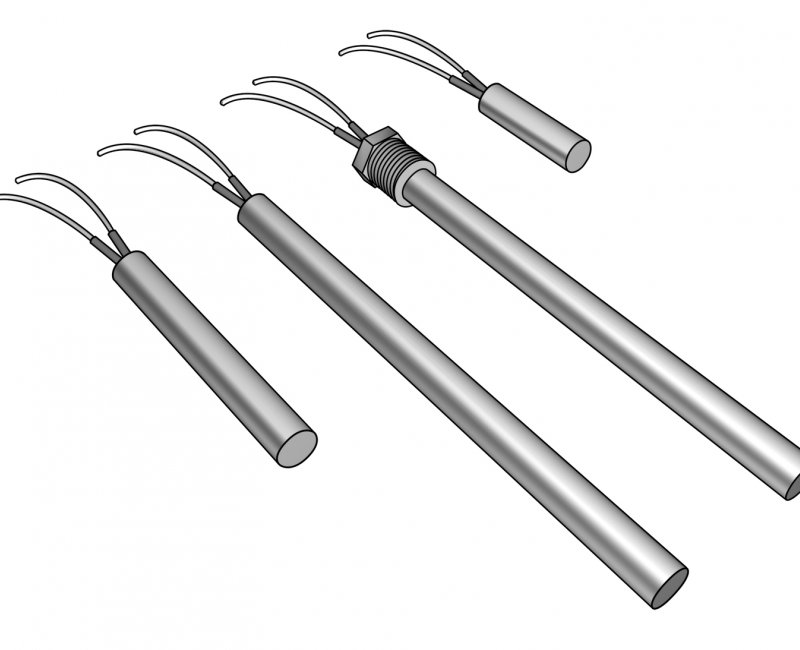

With products available in both metric and imperial sizes – from 6.5 to 16mm or from ¼” to ⅝” – as well as the option for bespoke measurements designed to suit the tightest specifications from any client – you’re sure to find the exact cartridge heaters you require.

Cartridge Heaters are commonly used in processes such as die casting, moulding and welding – but can even be found in the food production and medical industries.

So how exactly do cartridge heaters work? In this article, we explain a little more about the construction and function of these devices.

How do you construct a Cartridge Heater?

A resistance coil wraps around a ceramic core to design cartridge heaters that swiftly and effectively reach optimal temperatures. This design allows them to achieve any wattage or voltage with minimal risk of damage or condensation buildup when used correctly.

Manufacturers wrap dielectric material around the coil to mitigate risks associated with the electrical current. They then encase everything within a metal sheath.

The Heating Process

When activated, the device sends an electrical charge through the resistance coil, making it heat up. The coil then transfers this heat to the outer sheath, which in turn heats the target material.

Typically, you use a cartridge heater by drilling a hole, matching the heater’s size, into the material you want to heat and then inserting the heater’s body into that hole.

You should drill the hole according to the heater’s specifications (for example, drill a 10mm hole for a 10mm cartridge heater). Cartridge Heaters UK designs their heaters slightly smaller to simplify installation and removal.

If you select an incorrect heater diameter, your heater is likely to experience burnout – so be sure to order the correct size for your intended application.

It’s also a good idea to apply thermal grease to achieve the most effective heat transfer possible.

Where to Find the Right Cartridge Heater

If you’re looking for cartridge heaters for your own business or project, you can feel free to browse our range of products today.

Should you be unable to find the correct size or specification of cartridge heater for your needs, there’s no cause for concern.

Simply get in touch with our team today – either by calling 0044 0121 439 8932 or sending an email to sales@cartridgeheaters.co.uk and providing as much detail about your project or requirements as possible.

A member of our specialist team will talk through everything with you and help you to place an order for a bespoke device that precisely matches your unique specification. We look forward to hearing from you and assisting you in any way we can.