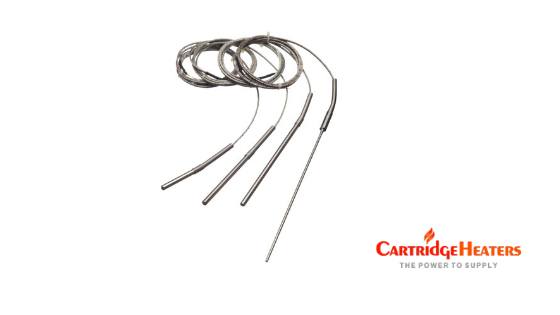

K type thermocouples are a reliable way to measure temperature and they offer many years of service – as long as they are used correctly. There are several factors that will affect both their accuracy and overall life expectancy. Here we take a look at the five most important in detail and offer advice and guidance on how to get the most out of your new temperature sensors.

5 ways to improve the lifespan of a thermocouple

-

Choose your thermocouple wisely

K type thermocouples may be the most commonly used type of thermocouple – but that doesn’t mean they’re always right for the job. This letter refers to the probe’s metal combination and it’s a good indication of its service temperature and accuracy. A K type probe is suitable for temperatures up to 1260°C, yet other types (e.g. J, S, T) are more suitable for higher and lower temperatures.

Be sure to do your research before you buy. Choose a temperature sensor that is right for your specific needs and you will achieve both optimal accuracy and a longer thermocouple lifespan.

-

Think about immersion depth carefully

Heat conducted away from the junction can often lead to inaccurate temperature measurements – which is why it’s important to consider the immersion depth of your K thermocouple carefully. Ideally, it should be used at a depth of (at least) 10 times its outside diameter. Bear this in mind before you make a purchase and select a probe length that is appropriate for your needs.

-

Avoid changing the depth

Once your K type thermocouple has been installed at a particular immersion depth, it needs to stay there. Any changes to its positioning can alter the output and lead to incorrect readings. Therefore, it’s a good idea to check the thermocouple whilst it’s in place. If you do need to remove the sensor, take great care to reinsert it at the exact same depth (or deeper) to avoid any errors.

-

Account for the effects of heating cycles

K type thermocouples are designed for use at a single or progressively higher temperature. This is when they are most accurate. However, if they do need to be used across a continuous cycle of temperatures, steps can be taken to reduce the chances of error. For example, you should make sure the thermocouple stays in optimum condition and conduct regular checks of the equipment.

-

Check them periodically

This may be an obvious point, but it’s important to check the condition of your K type thermocouple on a regular basis. Ideally, you should inspect it once a month, checking for any signs of excessive corrosion, oxidisation, general wear and tear and physical damage. If any issues are spotted, you should replace the temperature sensor as soon as possible to make sure readings are accurate.

Get in touch for further advice

If you would like to find out more about K type thermocouples and how to maximise their life expectancy, please feel free to get in touch. Our team of experts, here at Cartridge Heaters, demonstrate strong knowledge and experience in this area. Not only can they advise on the best thermocouple for your needs, but they can also offer useful tips and advice on its maintenance.

K type thermocouples can last for just a few hours or for many, many years – depending on how they are used – and we can help you to get the most out of your new equipment. So why not give us a call today on 0121 439 8932? Alternatively, send an email to sales@cartridgeheaters.co.uk and we will respond to your enquiry as soon as possible.