Whether referring to HVAC compressors, injection moulding manifolds or applications within the food services industry, cartridge heaters are essential components of numerous systems. These elements are built to highly exacting specifications and they are capable of producing as much power as 50 watts per square centimetre. However, much of this efficiency will revolve around how they are installed. An improperly positioned unit can sacrifice much of its heating power and in some circumstances, this can have a dramatic effect upon the entire system. So, what factors need to be taken into account during the installation of cartridge heaters?

Heat Transfer Concerns

It can be argued that one of the most important variables to take into account is heat transfer from the cartridge to the intended environment. In this manner, all holes need to be drilled precisely. The diameter of the hole must be uniform and free from any uneven surfaces (such as score lines or burs). If this aperture is not properly reamed, heat transfer will be compromised. So, precision tools should always be used and it is recommended that measurements are taken throughout the drilling process.

The Protection of Leads

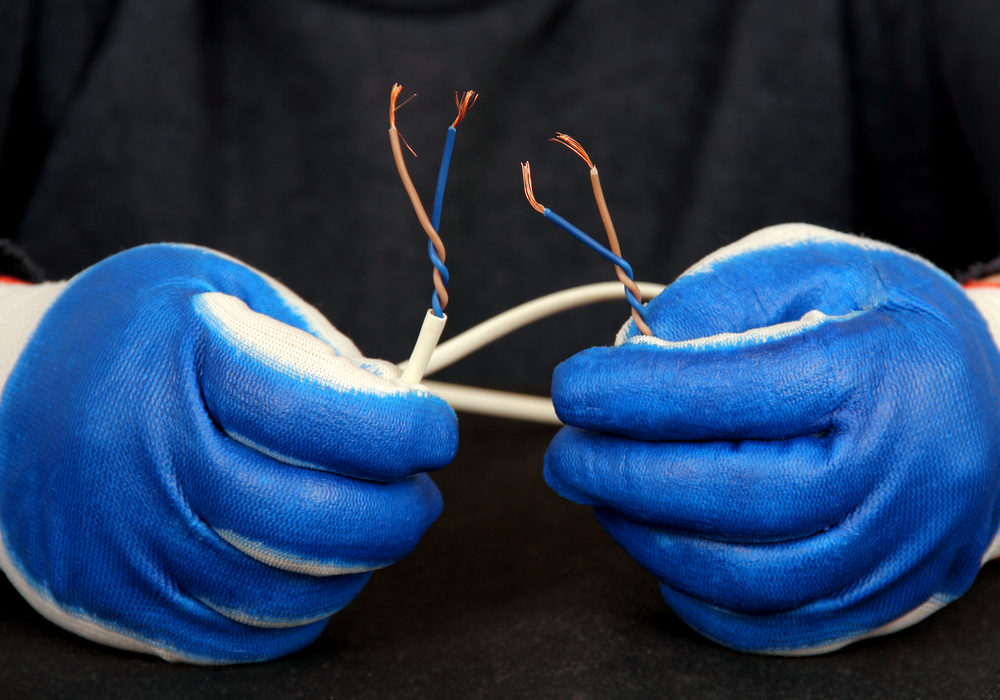

The leads to and from the heater itself are another very real concern. We must never forget that heat tends to be concentrated in the middle portion of the cartridge. If any connections are deeper than the hole that was drilled, there is a risk that the unit may short. The leads themselves could also burn or melt. So, it is critical that all of these connections are adequately protected. This can help to prevent any gases or liquids from exiting during operation.

Leads should similarly be protected from oils and sprays. Some of these substances are electrically conductive and may cause the unit to short circuit. This is also true with common insulation tape. Should the tape melt or carbonise, it can begin to unintentionally conduct electricity. Also, keep in mind the heat rating of the leads and make certain that the ambient temperature does not exceed this figure (normally 450ºC).

Temperature Monitoring

Cartridge heaters are intended to be used within a very specific temperature range. It is therefore crucial that each is installed after it has been properly calibrated utilising an approved gauge. Once the installation of all leads has been completed, they should once again be calibrated to make certain that no values have changed.

Other Concerns

There are some other variables that should be addressed. For example, a minimum of three heater diameters must be present between each installed unit. Every drilled hole must be equipped with an outlet so that removal is easier. Finally, lubricants such as graphite are not recommended during the installation process; some substances are conductive and may inadvertently touch the electrical leads of the heater.

These are some basic tips to address during the installation of cartridge heaters. please feel free to use this article as a guide or as a checklist in the future. Alternatively, call us on 0121 439 8932.