Next Day Delivery

Quality Promise

Refund Guarantee

Stock on Hand

Technical Specifications

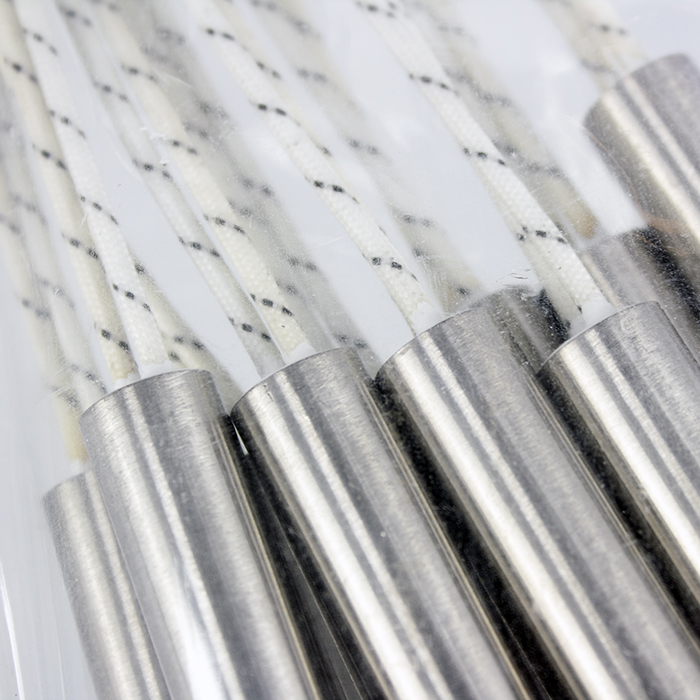

Materials

All of our cartridge heaters are made from stainless steel AISI 304/316/321/ INCOLOY and have:

- – a welded watertight tip (Tig) pressure up to 60 kg/cm2

- – a ceramic insulator

- – pure magnesium oxide insulation

- – nickel-chromium 80/20 heater wire (melting point 1400°C)

- – a ceramic core

- – heat-resistant conductor leads

- – conductor wire with internal connections

Technical details

They also share the exact same technical specification, listed below:

- 1. Maximum working temperature: 700°C

- 2. Diameter range (mm): 3mm – 40mm

- 3. Length range (mm): 15mm-3000mm

- 4. Diameter tolerance: metric -0.02/-0.06mm

- 5. Length tolerance: ±1mm

- 6. Power tolerance: +5%,-10%

- 7. Rated voltage (110-220): ≦1.27 times

- 8. Insulation resistance at 500VDC: ≧5mΩ

- 9. Designed life: 3000 hours

- 10. Power density:

Solids metals: 60w/cm2 (advisable 45w/cm2 max),

Water: 30w/cm2(max),

Heating static air: 10w/cm2(max),

Heating flowing air: 18w/cm2(max)

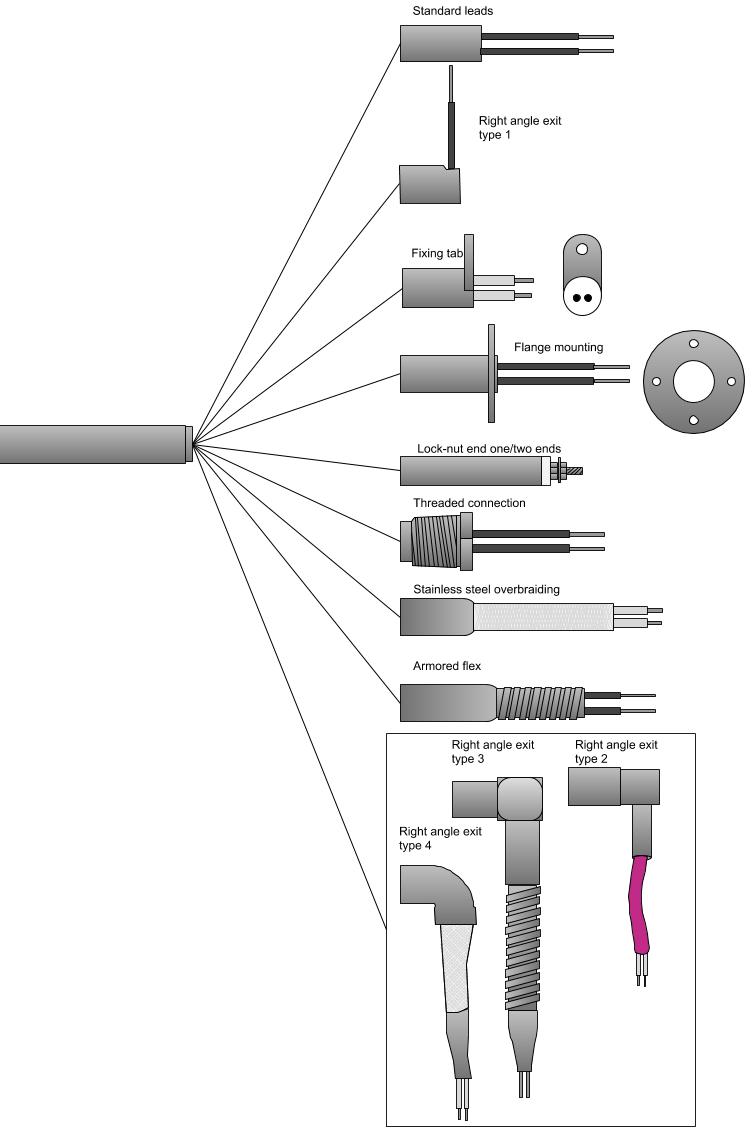

Cable termination designs

We currently supply cartridge heaters with a standard electrical connection OR with a range of other popular cable termination designs. These can be seen in the illustration below.

Cartridge heater FAQs

What are cartridge heaters?

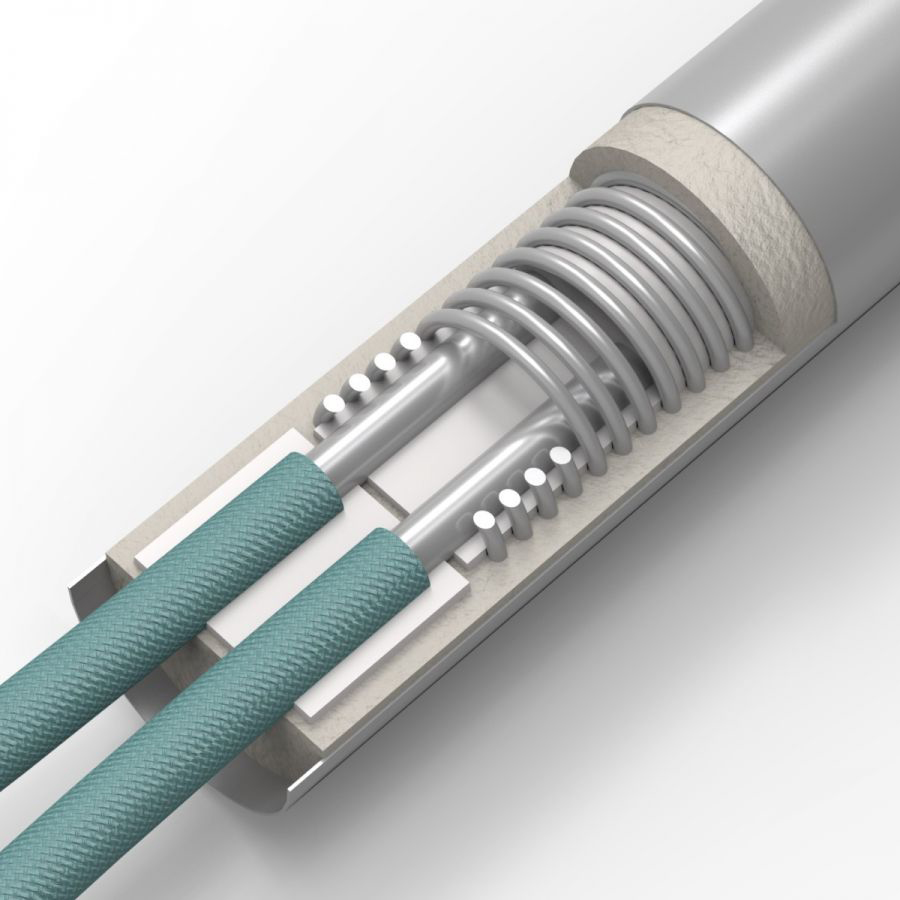

Cartridge heaters are a type of heating element designed to fit snugly into holes. They have a long cylindrical shape (made from stainless steel), inside which you will find a coiled resistive wire and an insulator. Reaching temperatures up to 750°C, they are an efficient way to heat up a nearby metal solid – and are commonly used to heat moulds, platens and dies.

How do cartridge heaters work?

The process can be broken down into 3 steps:

1. An electric current is passed through the coil to heat up the resistive wire

2. This heat energy is transferred via conduction to the metal sheath

3. Heat energy is then transferred via conduction from the metal sheath to the outside metal solid

100% of the energy is transferred from the electrical source to the metal solid in this way.

Which cartridge heater is right for me?

There are two important factors you need to consider when choosing a cartridge heater.

Firstly, the intended application. Here at Cartridge Heaters, we supply high watt densities as standard – but, if you think a low or medium watt density is better suited to your needs, this is something we can offer on request. The heating element can also be specifically adapted to your application; for example, with heated zones, special lead types and exits and thermocouple sensors.

Secondly, you need to think carefully about the size. All of our cartridge heaters are made using the highest quality materials to offer a long life under normal working conditions.

But, if the wrong size is chosen, self-heating and premature failure are likely.

So, be sure to do a little research – check out our blog for further guidance and feel free to contact our experts for advice.

Contact Cartridge Heaters UK today

If you would like to find out more about our cartridge heater technical specifications, you’re welcome to get in touch.

Call us on 0121 439 8932 OR send an Email to sales@cartridgeheaters.co.uk.